MZF4 in HSM Magazine

Innovation ISO: a new business school!

International model of governance for innovation promotes integration of processes and acceleration of results.

(Alexandre Pierro)

Technological acceleration has completely changed the business environment. Practices that were useful until recently no longer work – and companies have understood: they need to change. It is necessary to innovate all the time. But how? Despite all the information available, it is still difficult to generate value.

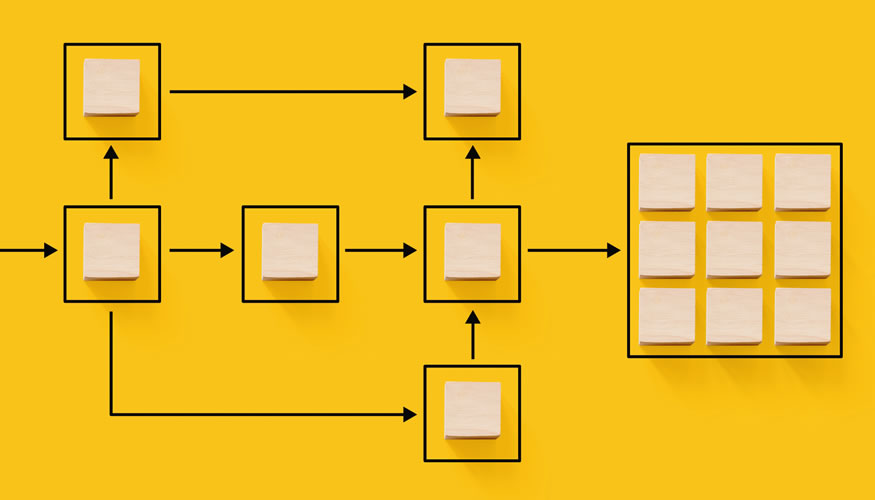

It is in this context that the ISO innovation appears, which is best understood as a business school, an international governance model for innovation that promotes the integration of processes and the acceleration of results. This guideline helps companies to create methodologies, tools, and indicators that ensure a state of permanent innovation and thereby become more competitive both locally and internationally.

In this special you will learn more about this management model through a practical approach, based on four common challenges in companies: (1) not being able to get ideas off the post-its; (2) having to decide in the midst of uncertainty and risk; (3) not having a culture for innovation; and (4) not innovating in an integrated and continuous manner. We also address the opportunities to foster innovation through tax refunds, via the Lei do Bem (Good Law).

To illustrate how the ISO innovation works, we bring real cases of Brazilian companies. They understood that this international framework is not only for large companies and that the implementation can be much simpler than one might imagine, without any risk of making the processes cumbersome or bureaucratic. These companies invested in an innovation project based on the tripod people, processes, and technology – and are already reaping great results. The next one could be yours! Welcome to the business school of innovation!

MZF4: Innovation in high added value products

Not getting the ideas out of the post-its

Hours of meetings, great ideas, and lots of colored post-its scattered around the room. Days, weeks, months go by, and nothing leaves the wall. Until one day they go to waste and all the work is lost. If the ideas were so good and the team was so excited, why didn’t they get off the paper? Simple! There were no processes to transform ideas into results. This was exactly the change that MFZ4, a spin-off of the Mazzaferro Group, a nylon transformation industry, experienced when adopting ISO innovation.

Since the implementation of this international governance model, the company, which has about 250 employees and family management, saw the rate of representation of new products in sales more than triple. Just in the first year after the adoption of this model, the company created 133 new products, which represented 9% of sales. Before, the record had been 2.5%. Today, this rate is already 12.5%, and it keeps growing.

The company was the first ISO certified in innovation in Latin America and the third in the world in 2019. With five business units, MZF4 is dedicated to developing higher value-added products from nylon. It produces items such as surgical sutures, dental brush threads, industrial sewing threads, hair dye wicks, musical strings, and brooms, which are supplied to about one hundred production chains in Brazil and exported to 60 countries.

The motivation for obtaining the ISO innovation was to improve product development and, mainly, to organize methods and processes. “When PALAS presented this model to us, it was still being formatted. We implemented the draft version, which brought us many challenges, but also many lessons learned,” remembers Fabrício Saad, a board member of the Mazzaferro Group, who led the certification process when he served as CMO of MZF4.

Within this innovation model, the company has structured some pillars, such as the Eureka program, in which employees are encouraged to contribute with ideas and receive awards when they are approved. “We have noticed a significant improvement in the organizational climate, including a reduction in turnover, since people feel much more motivated and committed to the company’s strategic objectives,” says Saad, who is also a professor of innovation at ESPM and the University of Salamanca, in Spain.

Three years after the certification, MZF4 reaps many positive results, such as improvement in customer satisfaction rates, partner relationships, team engagement and retention, and also increased brand value. The company also registered growth in exports (since ISO is a globally accepted business standard), in addition to process optimization, waste reduction, and even a drop in bank interest rates – since it offers a lower risk to financial institutions because it is prepared to deal with constant transformations. Another differential was the creation of an open innovation program, in which agreements were signed with universities in order to take advantage of the laboratories’ structure and the research being developed by master’s and doctoral students to create new products from nylon. One of the initiatives is a nanotechnology fabric.

With an eye on the future, the company is following research in several areas, aiming at the adoption of new materials and technologies to optimize production, generate added value, and contemplate sustainability. There are studies with graphene (a material with properties that make it possible to create intelligent threads and fabrics), researches to monitor the level of bacteria in bristles used in the health area, sutures that transmit information via IoT, among many others. With a well-established process, MZF4 guarantees that innovation is here to stay.

Port of Itaqui: a state-owned company at the forefront of innovation

Having to decide amidst uncertainties and risks

It is a mistake to think that everything remains static in the public sector. Besides the changes that take place from the outside, these companies also go through constant changes in management, since practically everything changes every four years, with elections. In this scenario, the great challenge is to build and leave a legacy for the population.

It was in the face of such a challenge that the Port of Itaqui, in São Luís, managed by the Maranhense Port Administration Company (Emap), decided it was necessary to place the issue within the business strategy. The latent question was how to guarantee that innovation would continue to be a priority, regardless of who would be in the administration in the coming governments.

The company already had innovation actions diluted among the areas, but lacked an integrated process that would guarantee the permanent continuity of the actions. It was then that the company chose to implement ISO, becoming the first public company in Brazil to adopt this methodology. “A model like ISO brings a standard to be followed. And even if, given the alternation of power to which we are subject, this theme is not a priority on the new agenda, there will be more chance of it being perpetuated, because a public commitment has already been made,” says Deborah Baesse, manager of communication and innovation at the Port of Itaqui.

In view of the knowledge acquired, the Porto do Itaqui Labs was created, a program that proposes to build innovative answers to improve processes. To this end, teams were formed with representatives of the port community, which, with the support of mentors, participate in a journey of innovation in order to develop prototypes and MVPs (minimum viable product). Among the guidelines is the creation of multimodal innovation, including road, rail and waterway transportation.

The Porto do Futuro program was created to support academic research in the port area. The initiative aims to attract talent and train specialized labor. “Our port complex is one of the largest in cargo handling in the country, and Itaqui is considered a hub in economy and logistics. We need to see reflected in the local academic community the interest and production of knowledge about the maritime and port sector,” says the president of the Port of Itaqui, Ted Lago.

In order to centralize all these initiatives and ensure the follow-up of ideas to innovation, the company relies on CRIARE.net, software developed by PALAS. With it, it is possible to centralize actions, making a precise follow-up of each stage of the innovation funnel, besides allowing better decisions, based on an intelligent algorithm that cross-references the resources available to innovate (whether time, knowledge, people, infrastructure or budget) with the ideas being developed. “The system allows us to visualize the processes in real time, which guarantees much more assertiveness in innovation,” emphasizes Baesse. This is the most accurate way to ensure the perpetuity of actions in the long term.

TMG: cutting-edge innovation for agribusiness

Not having a culture for innovation

One of the biggest challenges of innovation is to develop a culture where everyone feels stimulated and safe to present their ideas. Changing the mindset of employees, making them see the benefits in creating processes for innovation, was the first challenge faced by TMG, an agribusiness company that develops research for genetic improvement of seeds.

Although the drive to innovate has always been part of the company’s DNA, the implementation of the ISO innovation was crucial to obtain results that went beyond the laboratory. “Innovation naturally permeates our entire business, but we still felt the need to structure this activity and start defining standards for innovation management,” says Veridiana Vicentini, operations manager at TMG.

More than 50% of the staff is made up of researchers, with masters, doctors, and post-doctors. The goal was that, through the ISO approach, it would be possible to transform the various ideas into business opportunities.

An acculturation work had to be done, which included multidisciplinary group dynamics, events, and meetings to channel the ideas in a professional way, creating processes to know which ones to prioritize and how to treat them within an innovation funnel.

In the journey towards ISO, the intention was to implement good practices and consolidate them into a new innovation routine. “This goes far beyond the seal. It involves inserting the established protocols so that we can obtain real gains through innovation,” she says. After formatting innovation governance sponsored by the board, an intersectorial committee, policies, and templates for opportunity analysis were defined.

In this aspect, TMG also counted on the development of a trend study conducted by PALAS in partnership with LaraiaTech, a startup that uses artificial intelligence algorithms to transform data into strategic decisions. “We conducted a comprehensive study to identify possible opportunities and threats in agribusiness, seeking to understand the effects of climate change and agricultural pests,” said Lilian Laraia, the researcher responsible for the analysis.

As a company that invests in innovation research and development (RD&I), TMG has access to tax benefits from the Lei do Bem (Good Law), which acts as an important facilitator of innovation projects. With more integrated processes based on the ISO model, the company maximized the benefit, increasing the value of the refund. With the resources, it revitalized its biotechnology laboratory and bought new equipment that will support the demand for the next ten years.

Over this period, the company estimates an investment in research of around R$2 billion. “With new equipment added to the entire structure and standardization that we created to foster innovation, we will certainly have much more productivity and process improvements. This duo will provide us with even more promising results”, says Vicentini.

Atento: innovation that improves customer experience

Not innovating in an integrated and continuous way

In the same way that management focused on innovation brings a series of opportunities, it also generates many challenges. There are cases in which, after managing to start innovative projects, the leadership leaves and the actions simply do not have continuity.

In segments where employee turnover is usually above average, this can be even more challenging. This is the case of Atento, a contact center company that saw this scenario change with the implementation of the ISO innovation. With support from PALAS, the company was the first in the sector to receive certification. With an eye on the evolution of its service model, it created an area focused on creating and executing innovative solutions – a need that was heightened by the pandemic.

By adopting the methodology, its goal was to ensure a structured and organic innovation process, in order to always improve the customer experience. The initial diagnosis and the gap analysis helped to understand the details of ISO and to structure the actions. This stage, called assessment, evaluates the maturity level of innovation. And, regardless of whether the result is positive, the companies that proceed with the implementation have the opportunity to initiate actions that they did not yet have or even improve those that were underutilized.

Once the governance model formatting phase is over, which can last from four to six months, the company is ready to receive an internal audit, which makes the final validation of the process and, everything being adequate, it is cleared for the certification audit, which is performed by a certifying body that issues the certificate of compliance. “The certifier’s role is to evaluate and, mainly, ensure the maintenance of the processes, since we conduct a new audit in the company every 12 months, in order to continuously identify opportunities for improvement,” says Neifer França, director of QMS, certifier with more ISO innovation cases in Brazil.

The results appeared quickly. Atento restructured the innovation area and created a digital platform to manage the area’s two main initiatives: a program to stimulate the generation of ideas among employees and an open innovation program. “These actions have broken the myth that innovation comes only from the leadership, creating a culture that permeates the company as a whole, regardless of turnover,” reveals Bruno Pavani, the company’s innovation superintendent, who also highlights that the certification was well regarded by customers, shareholders and market analysts.

With the actions implemented, Atento was able to build a pipeline of operational innovations, transformational projects (such as the initiative to become data driven with machine learning), initiatives involving exponential technologies (conversational AI, metaverse), among others. “The ISO standardized and measured innovation within the company, structured the processes, and gave us maturity. Our case proves that the methodology does not restrict or bureaucratize innovation. On the contrary: it increases fluidity,” Pavani points out.

The resources are already inside your company. And you may not know it.

The opportunities of the Law of Good

Does your company already use the Law 11.196/2005, also known as the Law of Good? If not, you should consider this possibility. “This is the most comprehensive mechanism that exists today in Brazil to foster innovation in research, development, and technology. And it is the most comprehensive because, regardless of the sector in which the company operates – if it develops innovations in products, processes or services – it can obtain the benefits,” warns Rafael Costa, director of new business at FI Group, the largest consulting firm in fostering innovation in Brazil.

According to a report by the Organization for Economic Cooperation and Development (OECD), Brazil has the fourth highest company taxation among 109 countries surveyed. In this context, it is understandable that Brazilian businessmen seek opportunities to reduce their high tax burden. “With the Law of Good, it is possible to obtain an additional deduction of up to 80% of the expenditures classified as technological innovation for the purposes of the company’s taxable income,” explains Costa.

Several actions can be deducted by the Law, such as research to acquire knowledge about new phenomena or new knowledge about existing ones; work aimed at proving the viability of new products and processes; research in the area of basic industrial technology (development and improvements in machinery, equipment, and measuring instruments); and even technical support services for the deployment of facilities or equipment intended for innovation and technological research.

With so many benefits, it is surprising that adoption of the Good Law is not as great as it could be, despite all the advantages. “Data and documentation requirements discourage some managers, as they add complexity to the process. However, companies that implement ISO innovation track the necessary information more easily and are more prepared to benefit from the Act,” he assures. “The ISO provides companies with all the methodologies needed to effectively organize and implement innovation in order to optimize tax recovery. Without a doubt, it is a very effective investment with a fast return,” he adds.

Learn more about ISO innovation

• What is it: a methodology that offers guidelines for the implementation of an international governance model for innovation.

• When it came out: it was published in July 2019.

• Who can adopt: any company, regardless of size or segment in which it operates.

• Who has already adopted it: more than 400 companies worldwide, with more than ten in Brazil alone.

• In which sectors has it been applied: energy, steel, petrochemicals, aerospace, agribusiness, education, health, technology, and transportation, among others.

• Results obtained: creation of a customized governance model for innovation, well-defined processes and indicators, improvement of knowledge management, organizational culture, financial • results, employee engagement, capacity to deal with uncertainties and risks, and the company’s reputation in the market, among others.

• How long to implement: between four and six months.

• How much it costs: depends on the complexity of the company and the sector. Part of the investment can be recovered by the Law of Good.

• Why it matters even more in Brazil: it provides companies with an international model of innovation governance, with processes, methodologies and tools to make the country more competitive abroad.

Technological solution boosts tax refunds

If one of the biggest barriers to the adoption of the Good Law is document management, PALAS, a pioneering consultancy in the implementation of the ISO innovation, and FI Group, the largest consultancy in promoting innovation in Brazil, have teamed up to eliminate this problem. The companies have developed a connection between their technological platforms – CRIARE.net, which has intelligence algorithms that support leaders in decision making within the innovation funnel, and the Lei do Bem Digital Solution, which manages all projects eligible for the benefit – in order to optimize and enhance the tax refund process.

According to Rafael Costa, from FI Group, the partnership promotes a great benefit. “During the validation process, several ideas are discarded, and companies lose great opportunities for tax refunds because they don’t see the process as a whole. With the union between these two softwares, we will be able to increase the recovered values, allowing increasingly larger investments for innovation”, he highlights. “This is our opportunity to place Brazil among the biggest innovation players in the world. With a mature culture, well-established processes, and effective technologies, we will certainly have all the tools necessary to take our country to a new level of innovation and competitiveness,” concludes Alexandre Pierro, from PALAS.

Alexandre Pierro is a mechanical engineer, with a bachelor’s degree in physics and a master’s degree in engineering and innovation management from UFABC. He is a founding partner of PALAS, a consulting firm that pioneered the implementation of ISO innovation in Brazil, and one of the only Brazilians who participated in the process of formatting this management model with the international ISO TC/279 committee.

Published in HSM magazine (Brazil) on December 9th, 2022:

revistahsm.com.br/post/iso-de-inovacao-uma-nova-business-school